[Drying Equipment]Drying Equipment

본문

- Equipment & Facilities

-

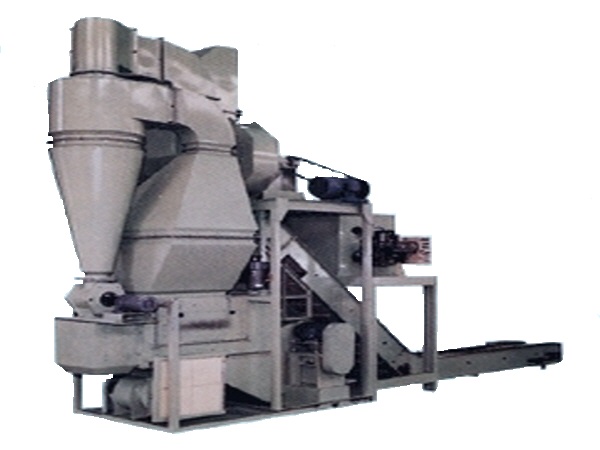

The inside of the dryer consists of the processes of blowing, circulating and discharching hot air in a closed chamber

The dried item is transported continuously for drying

Maximize drying efficiency by selecting various NET types

- Features

-

The product is forcibly passed through hot air to mass-process and ensure high efficiency

Products that are susceptible to breakage or scattering and those that have adhesive properties are acceptable

Easy configuration of temperature and wind speed circulation amount of hot air by zone according to the drying progresses

Convenience maintenance settings for maintenance and cleaning purposes

- Specifications

-

Available to design and manufacture according to customer needs in consideration of input product, water content, discharge amount, time and temperature, etc

- Applicable Products

-

-

Snack

-

Bean

-

Ginseng

-

Shred Pollock

-

Cereal

-

Fish cake for ramen soup

-

- Overview

-

The ingredients are put into a cylindrical drum that spins to be in contact with hot air for drying

Suitable for even drying production in large quantities

Mainly used for products that rarely become damaged

- Features

-

Evaporate moisture with the hot air circulation structure on the side

Product speed can be varied as the drums rotate through an inverter.

Even drying can be achieved for the ingredients which are easy to become attached to each other

Prevent adhesion between ingredients through quick surface drying

Achieve even drying through the rotary motions and the ascending effect of ventilation.

Neat drying results even with highly moist ingredients

Adaptable to changes in the water content of the ingredients

Available for continuous processing in large quantities under high temperature

Available for fine ingredients (approx. below 3 mm)

- Specifications

-

Capacity: 1950 Kg/Hr

Main power: 220V, 60Hz, 3Ph

Air: 5 kg/cm2

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Brown rice

-

Artificial rice

-

- Overview

-

The inside of the machine is divided into small cells

Suitable for the products which are vulnerable to breakage or temperature

Available for mass-market products as well as different kinds in small quantities

- Specifications

-

Capacity: 360kg / Batch

Size: W2000 x L2356 x H4400

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Mushroom

-

Carrot

-

Bean

-

Rice Snack

-

- Equipment & Facilities

-

Products are vibrated to become spread inside the dryer to achieve even drying

Suitable for adhesive products

Mainly used for primary drying of adhesive products

Suitable for quick surface drying

- Specifications

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Cereal

-

Extruded Products

-