[Packing Equipment]Packing Equipment

본문

- Overview

-

Packaging facilities that automatically supply and seal various products to the container (cup) and discharge them

Automatically feeds containers, products and additives into retainers that are intermittently driven by the pitch conveyor system

Available to select either the LID or film type after checking the feed status of the product and their weight

Release by sealing after confirming the status of the product

Minimize the release of defective products through monitoring and security function of the entire process

Maximize CFM performance with sophisticated safety sensors

Automatically and manually supply the subsidiary materials during the transfer process and discharge them after lid sealing

- Specifications

-

The production volume is classified by the number of containers to feed and the number of operating revolutions

Container rows can be selected from 2 to 4, 8, 10 and 12

Standard) Gerneral production capacity: 240 cups/min of 30 cycle with 8-row containerThe production speed of the container can be selected 30, 40, or 50 times per minute.

- Applicable Product

-

Container package products

(e.g., ramen, snack, confectionery, cereal, etc.) -

- Overview

-

Feed pouch package products that are cut and supplied from a distributing machine into containers

No blockage in vacuum pads. Adopts a suction type

Direct feed into the container regardless of the size of the pouch

Robots are used and two cylinders allow stable operation

You can choose between General Loading Machine and high-speed Loading Machine

- Specifications

-

General Loading Machine (SL200) : Supplies of 260 times per minute

high-speed Loading Machine (SL300) : Supplies of 360 times per minute

-

Pouch Size

Width 60mm ~ 100mm

Length 60mm ~ 120mmWeight : 2 ~ 30g (1Pouch)

*Other Size Consultation Request

- Applicable Product

-

Pouch type (soup broth, powder soup, vegetable sachet, noodle type)

-

- Overview

-

Automatically feed the products in a retort pouch to a distributing machine

Detect any abnormality in the products such as twist, cut, etc. in the soup pouch(sachets) during auto feeding

Applicable to various kinds of products

Available for belt type and roller type; can be selected according to the characteristics of the product

- Applicable Product

-

Soup pouch (sachets) in the liquid, powder, or dehydrated vegetable form contained in a retort pouch

-

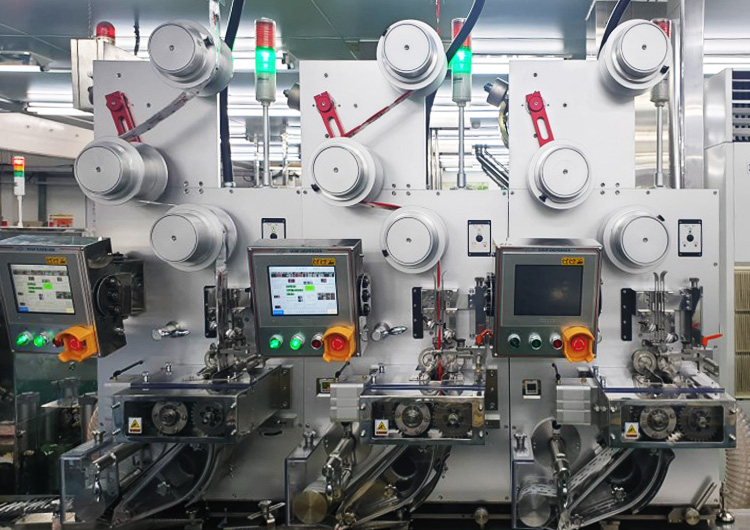

- Overview

-

Fills a small amount of powder or dehydrated vegetables into a retort form (attached in rows with one after another)

Available for high-speed mass production with three-sided sealing

Minimized quantitative error rate by rotary drum method and volumetric method

Production capacity with up to 950 pouches per minute

* Production volume may vary depending on the nature of the contents and the film characteristics

- Specifications

-

FILM WIDE : 160 ~ 220MM

FILM DIA : 350 ~ 450mm, 3"BOBIN

FILM SPEED : 50 ~ 72M/MIN

POWER : 220V, 3P, 60HZ, 6.2 ~ 7.2KW/HR

WEIGHT : 5g~25g

Packaging material : PET/AL/PE, PET/증착/PE, OPP/AL/PE

- Applicable Product

-

-

Soup powder

-

Vegetable sachet

-

Desiccant

-

Coffee

-

Tablet, Seasoning

Various kinds of powdered tea

-

- Overview

-

A facility for loading products discharged from a soup packaging machine in large capacity without twisting into a jumbo box(1,000*1,000*800)

Facilitate the production process when loading, transporting and supplying the packed soup powders

Various con'v systems are applied to enable automatic in-out emission.

- Specifications

-

Pouch Pitch: L80~95mm

A load carrying capacity: 10,000~25,000EA

Power: 220V, 60hz, 3-phase

Power consumption: Approx. 4.1 kw

Depends on the size and properties of the product.

- Applicable Product

-

liquid soup/soup powder, and dehydrated vegetable sachets packed in a retort pouch form

-

- Overview

-

Align and load products packaged in a retort pouch into a small box or paper box uniformly without entangling them

- Specifications

-

CAPACITY: 300 pouches/min (Based on 90-pitch soup powder)

DIMENSION: 1600W X 980L X 2200H (LOAD CAPA 4,000~8,000EA)

Power: 220V, 3P, 60HZ, 1.5 KW/HR

Depends on the size and properties of the product.

- Applicable Product

-

liquid soup/soup powder, and dehydrated vegetable sachets packed in a retort pouch form

-

- Overview

-

Available to cut out and feed even the packed forks or foldable spoons

Supply or put the products packed in a retort pouch (e.g., soup powder, liquid, dehydrated vegetables) into a separate packaging material by cutting them out

You can choose between General Soup Dispenser and high-speed soup Dispenser

Available to cut out and feed even the packed forks or foldable spoons

Detect where to cut out in a product:

1. Detect I-MARK

2. The pitch of each product is detected by the ultrasonic sensor

3. wrongly-cut sensingLow noise and accurate cutting quality with an error margin of within 2mm

Servo motor used for supplying and cutting a product ensures high speed operation with low noise

Specially treated blades ensure long service life and excellent durability

- Specifications

-

Speed: 150~400 pouches

* The production speed varies depending on the length and physical properties of the product, and other sizes need to be discussed with usPouch Size

Width 60mm ~ 100mm

Length 60mm ~ 120mm

- Applicable Product

-

Liquid/powdered soups, and dehydrated vegetable sachets packed in a retort pouch form, Packed forks, foldable spoons, etc.

-