- 미등록페이지

- Overview

-

Box transfer equipment capable of continuous upward/downward vertical movements

Available to transfer various types of boxes

transfer and discharge in multiple stages

- Specifications

-

Capacity: 18~20 BOXES/MIN

Electricity: 3.5 KW

Air: 0.1 ㎥/MIN

Temperature: 0~40 ℃

- Applicable Product

-

-

Box packages

-

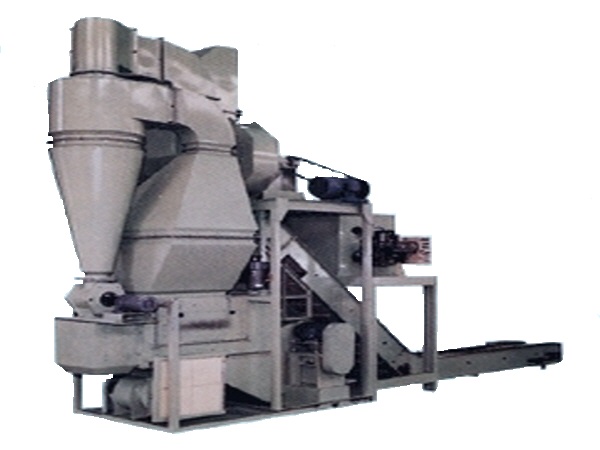

- Overview

-

Applied with the cyclone principle to sort out foreign matters

Sort out and remove impurities mixed in the product by resorting to a gravity difference in particles

- Specifications

-

Capacity: 200 Kg/Hr (Based on dry weight: specific gravity 0.0612)

Power: 200V 60Hz 3Ph

Air: 5Kg/㎠

- Sortable impurities

-

Heavy impurities: Stone, iron, plastic pieces and others

Lightweight impurities: Hair, thread, paper, vinyl, and other lightweight objects

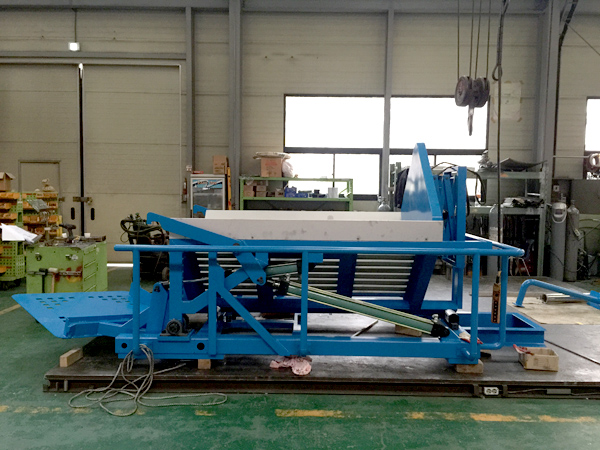

- Overview

-

A device that can separate the product (transported item) from the pallet to easily replace it with another pallet

- Specifications

-

Size: (W)2000 x (L)4500 x (H)2750mm

TANK: 50L

MOTOR: 5HP, 80V, 50Hz, 3Ph, DC24V

Capacity: 20~23 PALLET CHANGE/Hr

Maximum permissible load: 1Ton

Loadable height: 800~1500H

Power: 380V, 50Hz, 3Ph, DC 24V

- Overview

-

Maintain the specified temperature of the liquid product packed at a high temperature

Note) From the package temperature of the product (85 - 75℃) to the set temperature (35 - 30℃)The used coolant can be circulated to be reused

- Specifications

-

Capacity: 20~25M / min

Available package type: 3 or 4 sided soft retort pouch packaging

Example: (Vertical sealing: 8mm, crossing patterns: 0.8mm) or (Horizontal sealing: 10mm, crossing patterns: 0.8mm)Power: 3-phase 220V, 60Hz

Drain pump 1.5 Kw, Blower motor 1.3 Kw

* Custom order is available as per product temperature and production volume

- Applicable Product

-

Liquid pouch product packed in a retort pouch

- Overview

-

Use a burner (LNG) to heat the salt and have it inflated for the production

Simple cylindrical (drum) structure ensures good durability and easy maintenance

- Specifications

-

Salt dosage: 30KG * 17 sacks = 510KG

Passage time: 20 sec

Room temperature: 360°

Salt temperature: 220°

Exhaust temperature 170°

DIMENSION: 4700W X 1820L X 2600H

Production volume: 800 Kg/Hr

Main power: 220V 60 Hz 3ph

Power control: DC 24 V

Air: 6Kg/㎠

-

Custom order is available as per customer requirements

- Applicable Product

-

Pallet

- Overview

-

Put the fried product using a conveyor

Remove oil through high-speed spinning by batch

Automatically discharge the floating matters from the oil removed by stage, which are gathered at the bottom

Oil removed this way can be collected and reused

Multi-stage operation during discharge prevents accumulation of residue on the conveyor

- Specifications

-

DIMENSION: 1050W X 1200L X 2000H

-

Custom order is available as per customer requirements

- Applicable Product

-

Fried snack products

- Overview

-

A device that improves the movement and storage of wrinkles created by loading the box for a long time with hot air

Prevent malfunction when cutting the Soup Dispenser due to the fold of the soup

Hot air circulates internally and is controlled by a thermometer

- Specifications

-

Size: W680 x L1,475 x H1,600

Internal insulation: MINERAL WOOL

Internal and external cover: STAINLESS STEEL

Maximum air volume of hot air fan: 300 mmAq

Power Capacity: 220V 1P 2.5Kw

- Applicable Product

-

a soup packed in successively (liquid/flake/powder)

- Overview

-

Packaging facilities that automatically supply and seal various products to the container (cup) and discharge them

Automatically feeds containers, products and additives into retainers that are intermittently driven by the pitch conveyor system

Available to select either the LID or film type after checking the feed status of the product and their weight

Release by sealing after confirming the status of the product

Minimize the release of defective products through monitoring and security function of the entire process

Maximize CFM performance with sophisticated safety sensors

Automatically and manually supply the subsidiary materials during the transfer process and discharge them after lid sealing

- Specifications

-

The production volume is classified by the number of containers to feed and the number of operating revolutions

Container rows can be selected from 2 to 4, 8, 10 and 12

Standard) Gerneral production capacity: 240 cups/min of 30 cycle with 8-row containerThe production speed of the container can be selected 30, 40, or 50 times per minute.

- Applicable Product

-

Container package products

(e.g., ramen, snack, confectionery, cereal, etc.) -

- Overview

-

Feed pouch package products that are cut and supplied from a distributing machine into containers

No blockage in vacuum pads. Adopts a suction type

Direct feed into the container regardless of the size of the pouch

Robots are used and two cylinders allow stable operation

You can choose between General Loading Machine and high-speed Loading Machine

- Specifications

-

General Loading Machine (SL200) : Supplies of 260 times per minute

high-speed Loading Machine (SL300) : Supplies of 360 times per minute

-

Pouch Size

Width 60mm ~ 100mm

Length 60mm ~ 120mmWeight : 2 ~ 30g (1Pouch)

*Other Size Consultation Request

- Applicable Product

-

Pouch type (soup broth, powder soup, vegetable sachet, noodle type)

-

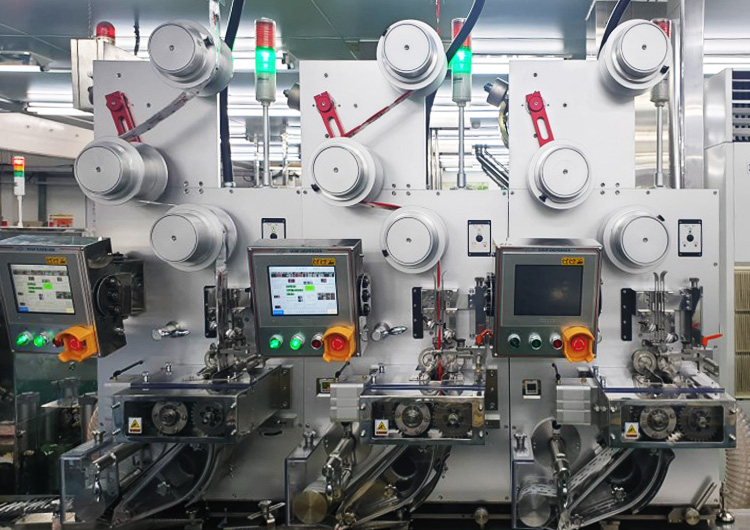

- Overview

-

Automatically feed the products in a retort pouch to a distributing machine

Detect any abnormality in the products such as twist, cut, etc. in the soup pouch(sachets) during auto feeding

Applicable to various kinds of products

Available for belt type and roller type; can be selected according to the characteristics of the product

- Applicable Product

-

Soup pouch (sachets) in the liquid, powder, or dehydrated vegetable form contained in a retort pouch

-

- Overview

-

Fills a small amount of powder or dehydrated vegetables into a retort form (attached in rows with one after another)

Available for high-speed mass production with three-sided sealing

Minimized quantitative error rate by rotary drum method and volumetric method

Production capacity with up to 950 pouches per minute

* Production volume may vary depending on the nature of the contents and the film characteristics

- Specifications

-

FILM WIDE : 160 ~ 220MM

FILM DIA : 350 ~ 450mm, 3"BOBIN

FILM SPEED : 50 ~ 72M/MIN

POWER : 220V, 3P, 60HZ, 6.2 ~ 7.2KW/HR

WEIGHT : 5g~25g

Packaging material : PET/AL/PE, PET/증착/PE, OPP/AL/PE

- Applicable Product

-

-

Soup powder

-

Vegetable sachet

-

Desiccant

-

Coffee

-

Tablet, Seasoning

Various kinds of powdered tea

-

- Overview

-

A facility for loading products discharged from a soup packaging machine in large capacity without twisting into a jumbo box(1,000*1,000*800)

Facilitate the production process when loading, transporting and supplying the packed soup powders

Various con'v systems are applied to enable automatic in-out emission.

- Specifications

-

Pouch Pitch: L80~95mm

A load carrying capacity: 10,000~25,000EA

Power: 220V, 60hz, 3-phase

Power consumption: Approx. 4.1 kw

Depends on the size and properties of the product.

- Applicable Product

-

liquid soup/soup powder, and dehydrated vegetable sachets packed in a retort pouch form

-

- Overview

-

Align and load products packaged in a retort pouch into a small box or paper box uniformly without entangling them

- Specifications

-

CAPACITY: 300 pouches/min (Based on 90-pitch soup powder)

DIMENSION: 1600W X 980L X 2200H (LOAD CAPA 4,000~8,000EA)

Power: 220V, 3P, 60HZ, 1.5 KW/HR

Depends on the size and properties of the product.

- Applicable Product

-

liquid soup/soup powder, and dehydrated vegetable sachets packed in a retort pouch form

-

- Overview

-

Available to cut out and feed even the packed forks or foldable spoons

Supply or put the products packed in a retort pouch (e.g., soup powder, liquid, dehydrated vegetables) into a separate packaging material by cutting them out

You can choose between General Soup Dispenser and high-speed soup Dispenser

Available to cut out and feed even the packed forks or foldable spoons

Detect where to cut out in a product:

1. Detect I-MARK

2. The pitch of each product is detected by the ultrasonic sensor

3. wrongly-cut sensingLow noise and accurate cutting quality with an error margin of within 2mm

Servo motor used for supplying and cutting a product ensures high speed operation with low noise

Specially treated blades ensure long service life and excellent durability

- Specifications

-

Speed: 150~400 pouches

* The production speed varies depending on the length and physical properties of the product, and other sizes need to be discussed with usPouch Size

Width 60mm ~ 100mm

Length 60mm ~ 120mm

- Applicable Product

-

Liquid/powdered soups, and dehydrated vegetable sachets packed in a retort pouch form, Packed forks, foldable spoons, etc.

-

- overview

-

Process by injecting the oil additive to the revolving blades (scraper) on the bottom surface and the upper head part

Gas burner type

Automatically set temperature up to 200°

Keep the scraper and the bottom surface of the pot at a certain distance to prevent carbides on the bottom of the pot

- Specifications

-

Capacity: 400L, 600L

Size: W2170 x L2020 x H1990

Stirring speed: 10 - 30 rpm

Mixing blade: 4 units (Teflon)

Main Power: 220V, 60 Hz 3Ph

Main fuel: LPG, LNG

Hydraulic pressure: 14Kw

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid souce and stir-fried ingredients

-

- overview

-

Secondary processing equipment that stirs liquid in the liquid form at high temperature

Recommended for stirring liquid products as it uses screw impeller

Prevent sticking to the inside through a scraper

The customer can choose whether to move the product down or sideways when discharging the product from the facility.

- Specifications

-

Capacity: 400kg, 800kg, 1000kg, 1500kg

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid Sauce

-

Paste soup sauce

-

- overview

-

Used to manufacture rice products such as snack pellets and rice cakes

Facilities for mixing mixed products other than flour by increasing the amount of water and steam

Steam spray nozzle installed inside

Discharged through the screw conveyor

Process by rotating the rod-type agitator or impeller pad to mix the ingredients together and then spraying it with steam

Equipment for making semi-finished dough

Use a hydraulic cylinder to control the doors of the product inlet and outlet

- Specifications

-

CAPACITY: 180 Kg/Batch 5회/Hr

Main Power: 220V, 60Hz

Produced in batches

-

Custom order is available as per customer requirement2

- Applicable Product

-

-

Wheat

-

Rice flour

-

- overview

-

It is an equipment that mixes various materials.

Depending on the customer's requirements, dumping stations, dust collectors, and sterilizers can be installed.

Choice of high speed and low speed rotation.

- Specifications

-

CAPACITY: 300L, 500L, 1000L

DIMENSION 1640W X 2800L X 1450H

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Powder

-

Mixed seasoning

-

- overview

-

Jacket structure type aligned to dynamic plane

Uniform heat conduction, minimized damage to the product, consistent food preparation

Useful for managing heat sources and maintenances through centralized control

Suitable for clean and hygienic work using stainless steel

Various options to choose the motion directions and types of impeller according to the properties and applications of the product

- Specifications

-

Capacity: 600L / 800L / 1000L

Size: 1200W X 3100L X 1700H (Based on 1000L)

Steam: 1.5~2.0 kg/cm2

Electricity: Inverter control, Control panel

Heat source: Steam (Gas, heat-powered boiler can be selected)

Options: Choose from estimation system, temperature sensor, timer, seal type

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid Sauce

-

- Equipment & Facilities

-

The inside of the dryer consists of the processes of blowing, circulating and discharching hot air in a closed chamber

The dried item is transported continuously for drying

Maximize drying efficiency by selecting various NET types

- Features

-

The product is forcibly passed through hot air to mass-process and ensure high efficiency

Products that are susceptible to breakage or scattering and those that have adhesive properties are acceptable

Easy configuration of temperature and wind speed circulation amount of hot air by zone according to the drying progresses

Convenience maintenance settings for maintenance and cleaning purposes

- Specifications

-

Available to design and manufacture according to customer needs in consideration of input product, water content, discharge amount, time and temperature, etc

- Applicable Products

-

-

Snack

-

Bean

-

Ginseng

-

Shred Pollock

-

Cereal

-

Fish cake for ramen soup

-

- Overview

-

The ingredients are put into a cylindrical drum that spins to be in contact with hot air for drying

Suitable for even drying production in large quantities

Mainly used for products that rarely become damaged

- Features

-

Evaporate moisture with the hot air circulation structure on the side

Product speed can be varied as the drums rotate through an inverter.

Even drying can be achieved for the ingredients which are easy to become attached to each other

Prevent adhesion between ingredients through quick surface drying

Achieve even drying through the rotary motions and the ascending effect of ventilation.

Neat drying results even with highly moist ingredients

Adaptable to changes in the water content of the ingredients

Available for continuous processing in large quantities under high temperature

Available for fine ingredients (approx. below 3 mm)

- Specifications

-

Capacity: 1950 Kg/Hr

Main power: 220V, 60Hz, 3Ph

Air: 5 kg/cm2

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Brown rice

-

Artificial rice

-

- Overview

-

The inside of the machine is divided into small cells

Suitable for the products which are vulnerable to breakage or temperature

Available for mass-market products as well as different kinds in small quantities

- Specifications

-

Capacity: 360kg / Batch

Size: W2000 x L2356 x H4400

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Mushroom

-

Carrot

-

Bean

-

Rice Snack

-

- Equipment & Facilities

-

Products are vibrated to become spread inside the dryer to achieve even drying

Suitable for adhesive products

Mainly used for primary drying of adhesive products

Suitable for quick surface drying

- Specifications

-

Custom order is available as per customer requirements

Designed in accordance with the input product, water content, discharge amount, drying time, temperature, etc

- Applicable Products

-

-

Cereal

-

Extruded Products

-