- 미등록페이지

- Overview

-

Box transfer equipment capable of continuous upward/downward vertical movements

Available to transfer various types of boxes

transfer and discharge in multiple stages

- Specifications

-

Capacity: 18~20 BOXES/MIN

Electricity: 3.5 KW

Air: 0.1 ㎥/MIN

Temperature: 0~40 ℃

- Applicable Product

-

-

Box packages

-

- Overview

-

Applied with the cyclone principle to sort out foreign matters

Sort out and remove impurities mixed in the product by resorting to a gravity difference in particles

- Specifications

-

Capacity: 200 Kg/Hr (Based on dry weight: specific gravity 0.0612)

Power: 200V 60Hz 3Ph

Air: 5Kg/㎠

- Sortable impurities

-

Heavy impurities: Stone, iron, plastic pieces and others

Lightweight impurities: Hair, thread, paper, vinyl, and other lightweight objects

- Overview

-

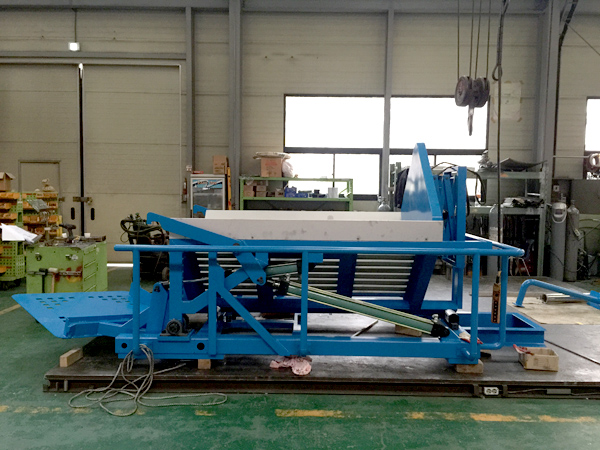

A device that can separate the product (transported item) from the pallet to easily replace it with another pallet

- Specifications

-

Size: (W)2000 x (L)4500 x (H)2750mm

TANK: 50L

MOTOR: 5HP, 80V, 50Hz, 3Ph, DC24V

Capacity: 20~23 PALLET CHANGE/Hr

Maximum permissible load: 1Ton

Loadable height: 800~1500H

Power: 380V, 50Hz, 3Ph, DC 24V

- Overview

-

Maintain the specified temperature of the liquid product packed at a high temperature

Note) From the package temperature of the product (85 - 75℃) to the set temperature (35 - 30℃)The used coolant can be circulated to be reused

- Specifications

-

Capacity: 20~25M / min

Available package type: 3 or 4 sided soft retort pouch packaging

Example: (Vertical sealing: 8mm, crossing patterns: 0.8mm) or (Horizontal sealing: 10mm, crossing patterns: 0.8mm)Power: 3-phase 220V, 60Hz

Drain pump 1.5 Kw, Blower motor 1.3 Kw

* Custom order is available as per product temperature and production volume

- Applicable Product

-

Liquid pouch product packed in a retort pouch

- Overview

-

Use a burner (LNG) to heat the salt and have it inflated for the production

Simple cylindrical (drum) structure ensures good durability and easy maintenance

- Specifications

-

Salt dosage: 30KG * 17 sacks = 510KG

Passage time: 20 sec

Room temperature: 360°

Salt temperature: 220°

Exhaust temperature 170°

DIMENSION: 4700W X 1820L X 2600H

Production volume: 800 Kg/Hr

Main power: 220V 60 Hz 3ph

Power control: DC 24 V

Air: 6Kg/㎠

-

Custom order is available as per customer requirements

- Applicable Product

-

Pallet

- Overview

-

Put the fried product using a conveyor

Remove oil through high-speed spinning by batch

Automatically discharge the floating matters from the oil removed by stage, which are gathered at the bottom

Oil removed this way can be collected and reused

Multi-stage operation during discharge prevents accumulation of residue on the conveyor

- Specifications

-

DIMENSION: 1050W X 1200L X 2000H

-

Custom order is available as per customer requirements

- Applicable Product

-

Fried snack products

- Overview

-

A device that improves the movement and storage of wrinkles created by loading the box for a long time with hot air

Prevent malfunction when cutting the Soup Dispenser due to the fold of the soup

Hot air circulates internally and is controlled by a thermometer

- Specifications

-

Size: W680 x L1,475 x H1,600

Internal insulation: MINERAL WOOL

Internal and external cover: STAINLESS STEEL

Maximum air volume of hot air fan: 300 mmAq

Power Capacity: 220V 1P 2.5Kw

- Applicable Product

-

a soup packed in successively (liquid/flake/powder)