- 미등록페이지

- overview

-

Process by injecting the oil additive to the revolving blades (scraper) on the bottom surface and the upper head part

Gas burner type

Automatically set temperature up to 200°

Keep the scraper and the bottom surface of the pot at a certain distance to prevent carbides on the bottom of the pot

- Specifications

-

Capacity: 400L, 600L

Size: W2170 x L2020 x H1990

Stirring speed: 10 - 30 rpm

Mixing blade: 4 units (Teflon)

Main Power: 220V, 60 Hz 3Ph

Main fuel: LPG, LNG

Hydraulic pressure: 14Kw

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid souce and stir-fried ingredients

-

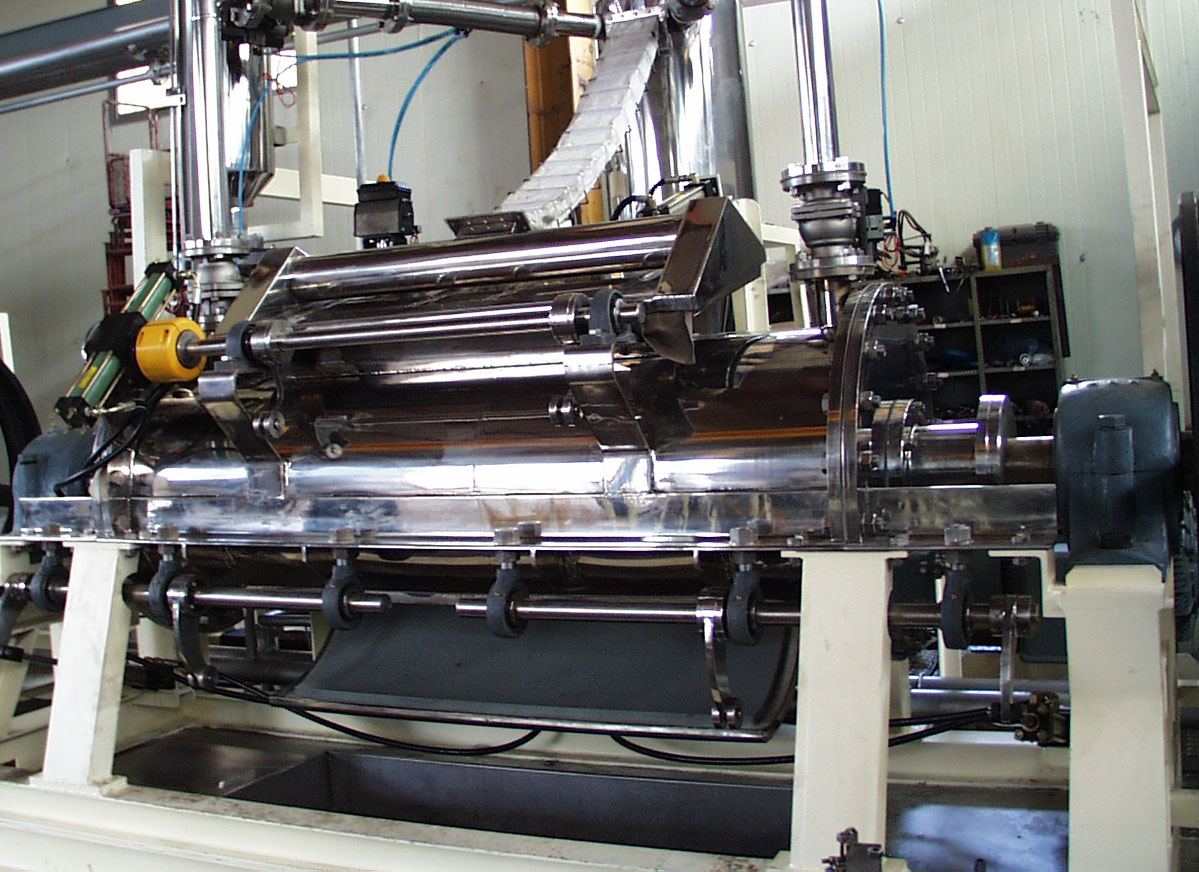

- overview

-

Secondary processing equipment that stirs liquid in the liquid form at high temperature

Recommended for stirring liquid products as it uses screw impeller

Prevent sticking to the inside through a scraper

The customer can choose whether to move the product down or sideways when discharging the product from the facility.

- Specifications

-

Capacity: 400kg, 800kg, 1000kg, 1500kg

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid Sauce

-

Paste soup sauce

-

- overview

-

Used to manufacture rice products such as snack pellets and rice cakes

Facilities for mixing mixed products other than flour by increasing the amount of water and steam

Steam spray nozzle installed inside

Discharged through the screw conveyor

Process by rotating the rod-type agitator or impeller pad to mix the ingredients together and then spraying it with steam

Equipment for making semi-finished dough

Use a hydraulic cylinder to control the doors of the product inlet and outlet

- Specifications

-

CAPACITY: 180 Kg/Batch 5회/Hr

Main Power: 220V, 60Hz

Produced in batches

-

Custom order is available as per customer requirement2

- Applicable Product

-

-

Wheat

-

Rice flour

-

- overview

-

It is an equipment that mixes various materials.

Depending on the customer's requirements, dumping stations, dust collectors, and sterilizers can be installed.

Choice of high speed and low speed rotation.

- Specifications

-

CAPACITY: 300L, 500L, 1000L

DIMENSION 1640W X 2800L X 1450H

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Powder

-

Mixed seasoning

-

- overview

-

Jacket structure type aligned to dynamic plane

Uniform heat conduction, minimized damage to the product, consistent food preparation

Useful for managing heat sources and maintenances through centralized control

Suitable for clean and hygienic work using stainless steel

Various options to choose the motion directions and types of impeller according to the properties and applications of the product

- Specifications

-

Capacity: 600L / 800L / 1000L

Size: 1200W X 3100L X 1700H (Based on 1000L)

Steam: 1.5~2.0 kg/cm2

Electricity: Inverter control, Control panel

Heat source: Steam (Gas, heat-powered boiler can be selected)

Options: Choose from estimation system, temperature sensor, timer, seal type

-

Custom order is available as per customer requirements

- Applicable Product

-

-

Liquid Sauce

-